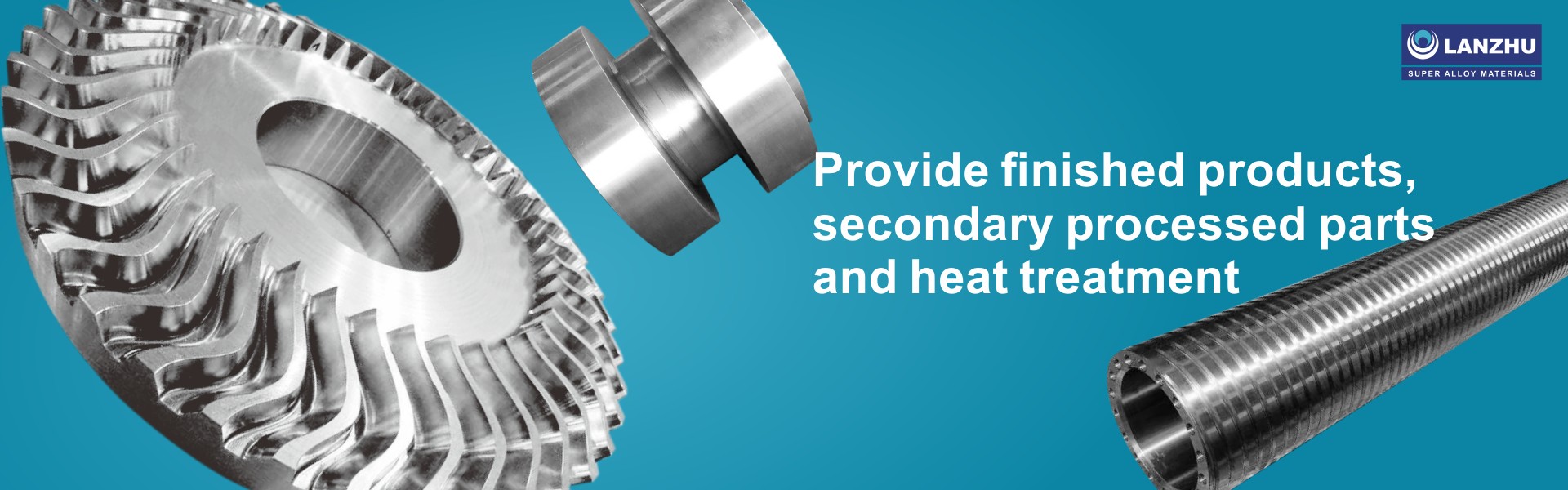

About Us

Shanghai LANZHU Super Alloy Material Co. , Ltd. was established in 2005. It is a manufacturer of nickel alloy and cobalt alloy materials. Through vacuum smelting, electroslag remelting, free forging, die forging and process, provide end nickel alloy, cobalt alloy forgings, profiles, valve bodies, ring forgings. Shanghai bluecast has been committed to the research and development of nickel alloy and cobalt alloy material processing technology for many years, which can solve the practical application of material value-added technology in compl...

-

Incoloy ®800H seamlness tube,pipe,ring,Sleeve

-

Hastelloy®X seamlness tube,pipe,ring,Sleeve

-

Hastelloy®C-276 seamlness tube,pipe,ring,Sleeve

-

4J32 Forging,Strip,Sheet,Seamless pipe.Bar,Precision casting,3D Metal powder(32HКД,32HК-BИ,Super-Invar,Super-Nilvar,SI,Invar,Superieur)

-

Hastelloy®C-276 Forging,strip,bar,ring,spring,bolt,Pipe fitting,3D Metal powder,precision casting(UNS N10276, W.Nr.2.4819, NiMo16Cr15W, NC17D)

-

Incoloy®800 casting,Sheet,strip,Pipe.Forgings,Precision casting,3D Metal powder(UNS N08800,0Cr20Ni32AlTi,No8800,NCF800,X2NiCrAlTi3220)

-

Monel®K-500 Bar,pipe,valve seat,sphere,flange,forging,precision casting,3D metal powder(UNS N05500,Ni68Cu28Al,W.Nr.2.4375)

-

Monel®400 forging,tube (UNS N04400/W.Nr.2.4360)The most resistant to seawater corrosion alloys

-

Hastelloy®C-276 forging,Die forging(UNS N10276, W.Nr.2.4819,Nickel alloyC-276)

-

Inconel®718 Strip,thin strip, precision strip(UNS N07718,W.Nr.2.4668,Alloy 718)

-

Inconel®718 High temperature resistant corrosion resistant spring,(UNS N07718,W.Nr.2.4668,Alloy 718)

-

Inconel®718 High temperature and high strength bolt and nut(W.Nr.2.4668 bolt)

-

Inconel®718 Seamless tube(UNS N07718,W.Nr.2.4668,Alloy 718)

-

Inconel®718 Forged long shaft,principal axis(Inconel®718 ,N07718,W.Nr2.4468)

-

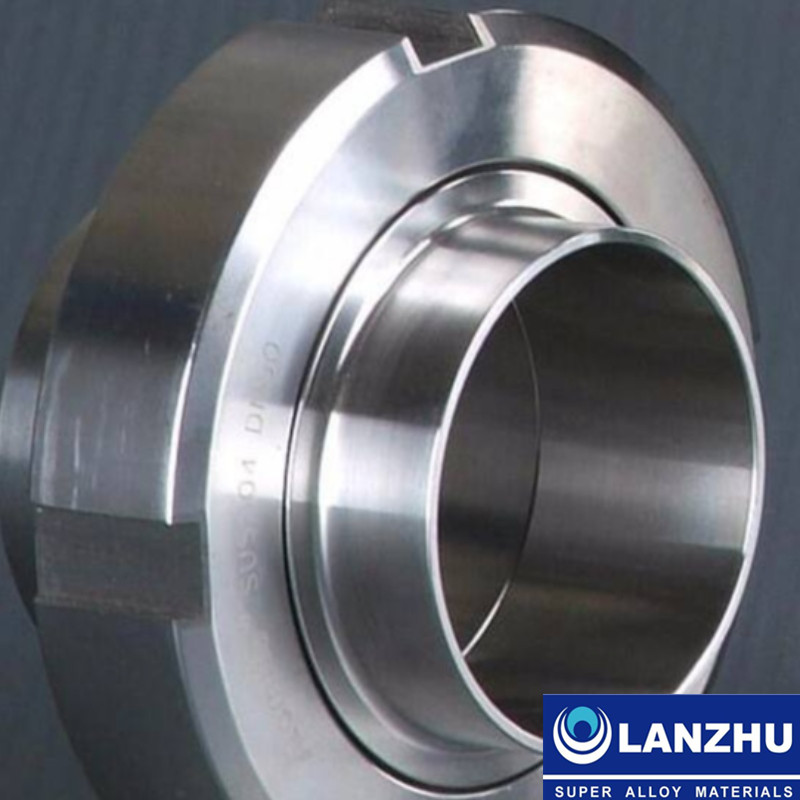

Inconel®625 Sleeve, ring, disc(alloy625,UNS N06625,W.Nr.2.4856,NiCr22Mo9Nb,NA21)

-

Inconel®718 Tubing hanger ,Sleeve Bushing(UNS N07718,wwW.Nr.2.4668,Alloy 718)

-

Super stainless steel

-

Diameter 100 GH4169 bar

-

Inconel®X-750 Bar

-

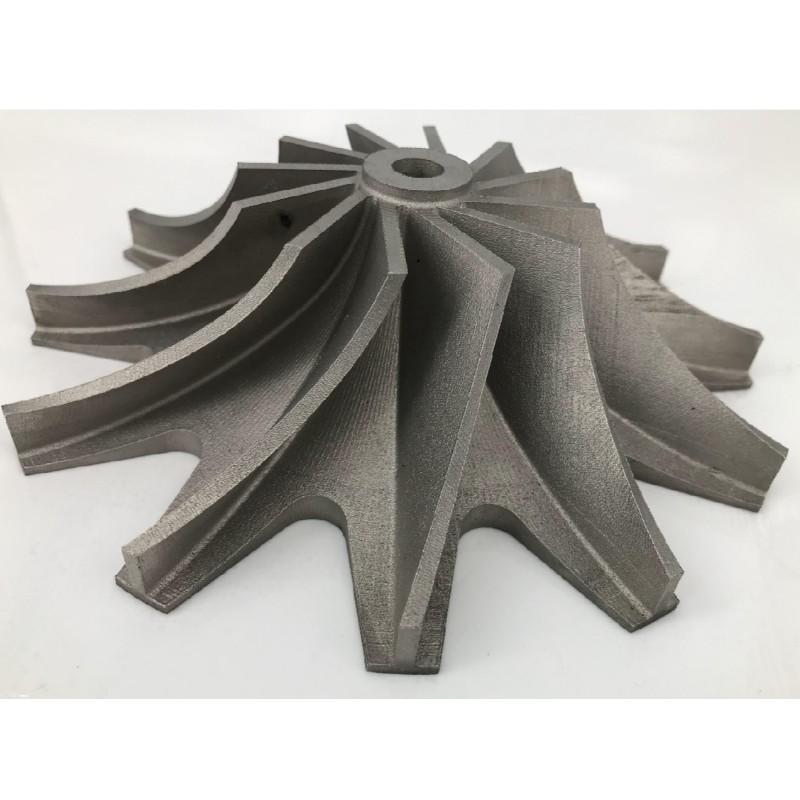

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (3)

-

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (2)

-

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (1)

-

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (4)

-

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (5)

-

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (6)

-

75KW and 150KW Inconel®718 alloy mechanical accessories-upper and lower mandrels

-

Inconel®625 3D metal powder spot inventory

-

Invar36 3D metal powder spot inventory